ER4047 aluminum welding wire is a welding material used for welding or surfacing of light alloy processing industry, with the characteristics of low melting point and good fluidity.

Aluminum Silicon Alloy Welding Wire ER4047

ER4047 aluminum welding wire is a welding material used for welding or surfacing of light alloy processing industry, with the characteristics of low melting point and good fluidity.

1. Product information:

Name: Flux-cored welding wire

Product model: 4047

Product specification: φ2.0,φ1.6 ect.

Product composition: Aluminum-silicon alloy wrapped with non-corrosive aluminum brazing flux

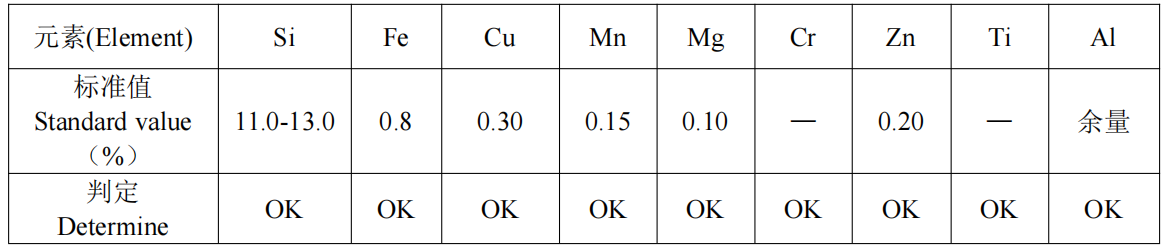

2. Chemical composition test table:

Leather material technical standard number (Specification): GB/T 10858-2008

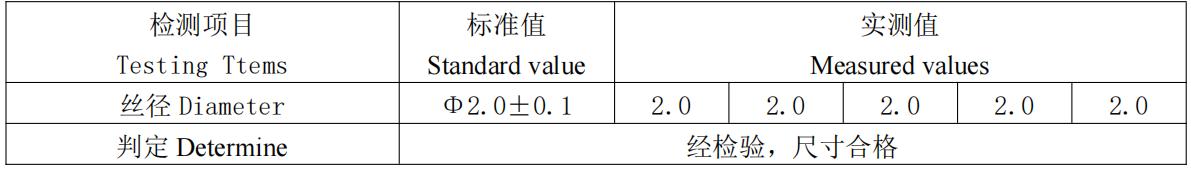

3. Size inspection table:

4. Wire appearance inspection results:

After inspection, the wire surface is smooth, without burrs, pits, scratches, cracks, oil stains or other impurities and defects, and meets the inspection standards.

5. Some material characteristics:

Aluminum silicon metal melting temperature (solidus-liquidus/℃): 574℃-585℃;

Aluminum brazing flux melting temperature range: 550℃-572℃;

Aluminum brazing flux composition: KALF4 and K2AlF5・H2O.

6. Material use and precautions during use:

The material is used for brazing of aluminum and its alloys, and pressure brazing of aluminum and stainless steel;

Please provide safety protection for operators during use to prevent high-temperature liquid molten materials from splashing and injuring the human body.